Our continuous improvement policy

As you may know, EKKO-MEISTER is working on a few big projects this year. We’ve already mentioned an improved website that’s coming soon.

One of our other important projects is even better & efficient quality control.

Metal stamping tends to generate tiny metal shavings and slight abrasions. But small surface defects in grooved bearing washers can lead to higher wear or more noise.

To ensure the high quality of our bearings, all faulty parts need to be eliminated. In the past, this was done by hand.

But with millions of parts produced each year, you can imagine how tedious this was…

Custom high-speed quality control

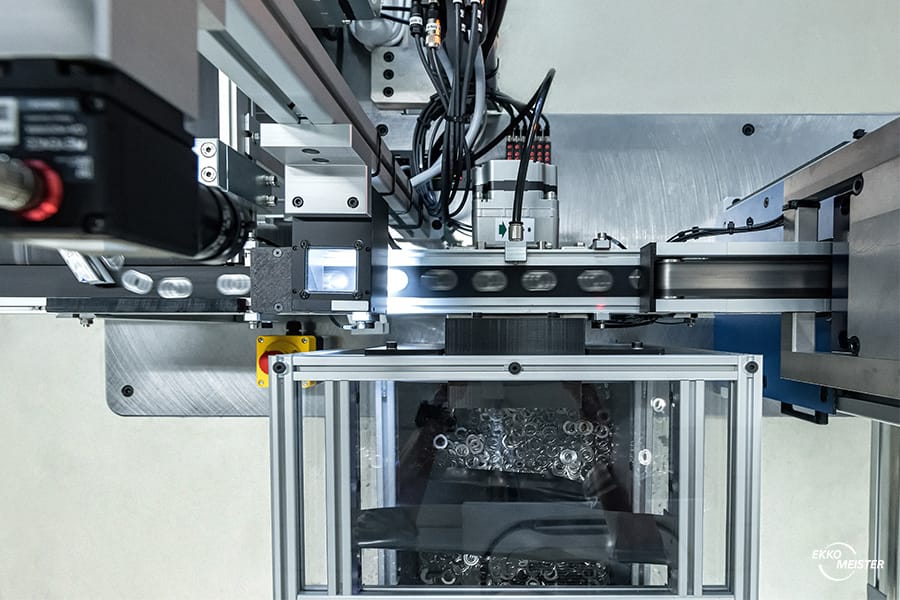

Fortunately, we have the necessary engineering talent in-house to build a custom, high-speed test station that inspects and sorts 100% of these washers.

It checks the parts for surface defects like indentations, scratches, or discoloration.

At a speed of 10 parts/second, these bearing washers are controlled from above and below by two cameras.

Since the reaction time is only a few milliseconds, it was a bit challenging to achieve the right interaction between the different sensors & valves to sort out faulty parts.

But after several months of meticulous planning, installing, programming, testing, and tweaking, the machine is ready.

Better customer value

For our clients, this means we can ensure an even more reliable high quality. And this is what it’s all about and what drives us.

We are constantly looking for ways to make great products and processes even better.

So feel free to contact us if you’d like to find out more about how we work and what we can do for you.

Leave A Comment