A Chat about Simultaneous Engineering, Automation, and Potential with Ekko-Meister’s Chairman

It’s not every day we get to chat with our chairman. Mr. Sahli, would you tell us how your journey led you to Ekko-Meister?

I have always been fascinated by the challenge of using outstanding technology and maximum precision to reliably manufacture parts in large series for major international customers. I focused primarily on non-cutting production methods and a broad material base.

In 2012, I joined the then Ekko Technik AG as a member of the Board of Directors and later took on the role of Chairman, tasked with a thorough modernization by the shareholders.

Could you give us a brief overview of how the company has evolved since then?

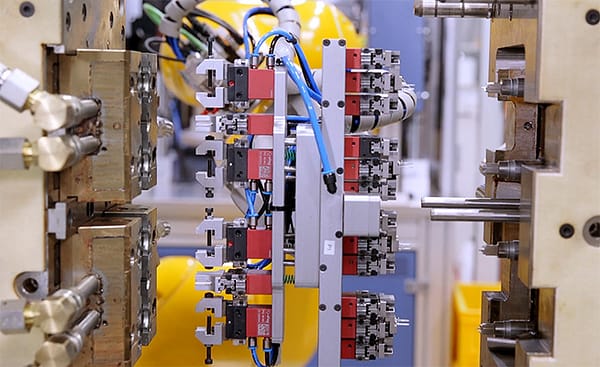

Ekko-Meister has quickly established itself as a technology supplier. We have expanded our services to include new production technologies such as plastic injection molding, surface treatments, and even fully automated assembly systems.

Because we were growing so fast, we ended up building a new company and production site in Grenchen which we moved into in the fall of 2022.

Ekko-Meister specializes in custom-made solutions. How do you meet the individual needs of your customers?

Thanks to an ambitious investment program, we have created a solid foundation and brought our engineering and tool-making capabilities to top levels.

Plus, we can develop and manufacture the necessary automation for interlinking all process steps in-house, which is a significant advantage.

After all, our clients expect a comprehensive package of solutions at an attractive price.

How do clients benefit from Ekko-Meister’s extensive experience and expertise?

From simultaneous engineering and prototyping to the delivery of ready-to-install parts, we offer our clients a comprehensive, reliable, and competitive package. Simultaneous engineering means that design, prototyping and production preparation go hand in hand.

This enables us to react immediately to feedback and make adjustments.

For our clients, this leads to faster development times, enhanced product quality through immediate improvements, and seamless coordination of all processes.

Are there plans to further expand your technologies?

Thanks to our innovative process developments, together with new customer projects, we’re constantly fine-tuning and expanding our production technologies.

This naturally has a positive effect on other projects as well, and is an ongoing rather than a one-time event.

So, there are innovations that have come directly from client feedback or requirements?

Yes, there are. Conversations with our clients have led to innovative insights for both sides.

However, for contractual reasons, I can’t go into detail here.

Your clients work in a wide range of sectors. How do you meet the specific requirements of each industry?

Ekko-Meister continuously monitors market developments in the individual sectors and adapts its strategy accordingly. We have been ISO 9001 and IATF 16949 certified for years.

With an ISO 13485 certification, for example, we can prepare ourselves for a broader entry into the medical market.

It seems like everyone is talking about AI right now. What’s Ekko-Meister’s take on global trends like automation and artificial intelligence?

We’re pretty well positioned in terms of automation and the know-how we have built in-house. As for AI, the world is just at the beginning of an exciting development.

Thank you, Mr. Sahli. Lastly, what opportunities and challenges do you see for Ekko-Meister in the near future?

The new production site and our investments in technology have received a positive response from both customers and the job market – creating new opportunities for us. Producing hybrid parts and small assemblies in particular opens up great growth potential and defines our offer.

Of course, political, religious, and other disruptions, as well as the impact of climate change and social issues, create a volatile mix. We must diligently watch the developments and be ready to adjust our strategy, a process that often requires decisive action.

In this context, it’s not the big who eat the small, but the fast who leave the slow far behind.

Leave A Comment