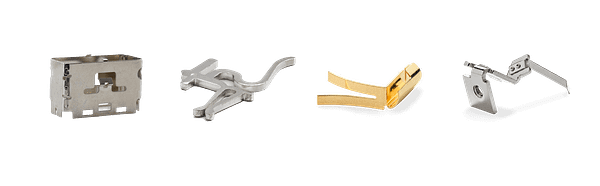

Our stamping department at your service

Every year, our stamping department transforms plenty of raw metal – from DC01 steel, Mu-metal, beryllium copper, to titanium – into custom parts for companies like yours!

Large production quantities of 100 million metal stamped parts per year are not unusual, medium quantities of between 20 and 30 million parts are the norm.

Depending on your material and geometry specifications, we can produce quantities starting from just a few thousand parts. We have a very cost-effective production capability for small production runs.

Whichever your industry

From automotive and aerospace to consumer goods, medical technology and more – we’ve got you covered.

AUTOMOTIVE:

Valve control for the internal combustion engine, sealing rings for spark plugs, components for stepper motors and electronic contacts

MEDICAL TECHNOLOGY:

Sterilizable titanium metal products for medical packaging as well as electrical contacts. Components for assistance robots

ELECTRONIC ENGINEERING:

Components for mechatronic drives such as stators and rotors, electrical contacts and conductor connections. E-bike and control elements for public transport

CONSUMER GOODS:

Stamped parts for electrical contacts and connections. Various components for sensors

BUILDING ENGINEERING:

Sensor elements for energy monitoring as well as contacts and electric actuators.

Power and energy systems

VARIOUS INDUSTRIES:

Components for power tools, elements for sewing machines, various components for security & defense

Our diverse selection of materials and surface finishes ensures that you get components that perfectly fit your needs.

You’ll also appreciate our additional operations – from rigorous heat treatments to detailed post-processing, such as deburring and cleaning.

And your greatest advantage?

Thanks to our complete in-house service, you get everything from a single source – from the design phase to your finished series product. This saves time, money and effort.

And this applies both to metal components and plastic-metal assemblies thanks to our fully equipped, modern plastic injection molding department.

From the start, our engineers work with you to design your product, create custom tooling with our tooling department, and even develop and build tailor-made manufacturing cells if needed.

As you can see, stamping, forming and deep drawing is about more than just manufacturing parts for us – it’s about developing the best solution for your project.

So, take advantage of our comprehensive support to bring your parts to life.

Leave A Comment