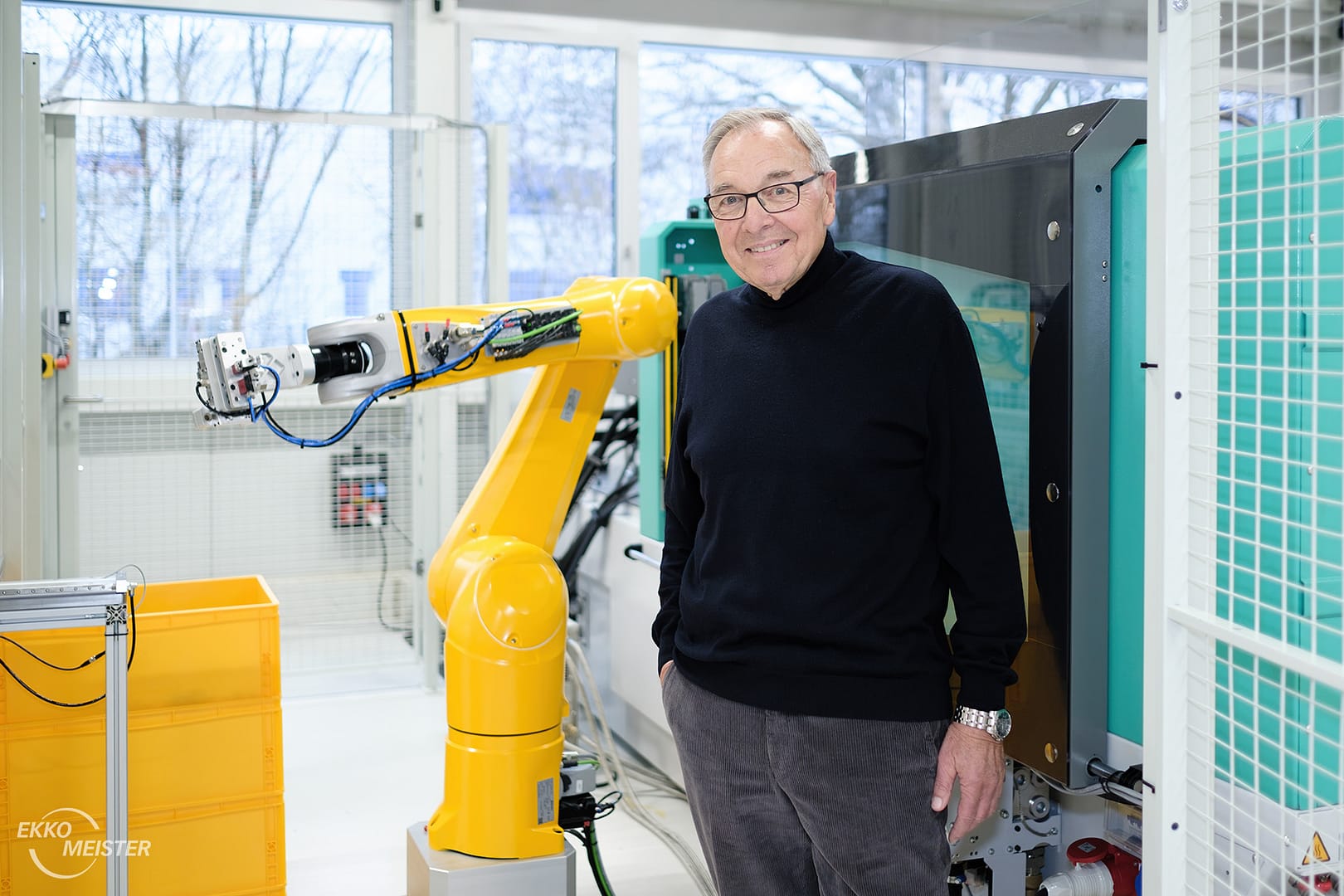

Interview with our chairman, Walter Sahli

2022 was an eventful year for EKKO-MEISTER AG. It’s the perfect occasion to ask our chairman to review the year and to tell us what the future has in store for us.

Mr. Sahli, can you briefly introduce yourself and your background?

For close to 30 years, I managed companies in the supplier industry, involving various technologies such as powder metallurgy, plastic injection molding, stamping, forming and fineblanking. In more recent years, I have been able to provide strategic and advisory support to companies such as EKKO-MEISTER AG as a member of their Board of Directors. This gives me great pleasure and satisfaction, especially when accompanying an expanding and future-oriented company like EKKO-MEISTER AG. I truly enjoy working with people in a team.

How long have you been with EKKO-MEISTER (and how did this come about)?

In 2012, I was appointed to the Board of Directors of what was then EKKO-Technik AG. Together with shareholders and the management, I was tasked to develop and implement a strategy for the future.

The last few years have been eventful. What are the most important milestones?

It’s true that a lot has happened.

- In 2014, I was introduced to Martin Meister. Hans Meister AG was an important supplier to EKKO at the time, and our product portfolios complemented each other well. For different reasons, both companies were ill-positioned for the future and had poor chances of survival in the medium term. That’s why I worked out plans with Martin Meister on how the companies Hans Meister AG and EKKO-Technik AG could be developed further.

- In 2017, the two SMEs merged to form today’s EKKO-MEISTER AG. This process was very challenging and required tough decisions at times that affected both employees and shareholders.

- In 2019, the rapid development of our new company proved that we were on the right strategic track. We urgently needed an expansion which wasn’t possible at the Lengnau site for various reasons. So, we decided on a “greenfield” project in Grenchen.

- In 2022, we moved into the new building, which opened up completely new perspectives for us and our customers.

It’s a huge undertaking to build a new factory. Please tell us a little more about how this came about!

As I mentioned earlier, the market response after the merger was very positive and we grew considerably. It quickly became clear that we needed more space for additional technologies and capacities if we wanted to provide our customers with high-quality products and a more comprehensive service in the long term.

Grenchen offered us the ideal conditions for our new factory, and its authorities were very helpful.

Did everything go according to plan, or did you have to improvise?

Not everything went exactly as planned. That would be quite unrealistic for such an extensive project. But regarding deadlines and building engineering, the promises were largely kept. Nevertheless, the final phase with the move itself required some improvisation. A real Herculean task for Martin Meister and the entire EKKO-MEISTER team.

We didn’t quite stay within the budget, though. Anyone who has ever built anything probably has experienced this. The extra costs were due to additional requests, material cost increases and other factors. But thanks to our industry-focused shareholders and our house bank, we avoided all pitfalls.

What was the most exciting thing for you this year?

The biggest challenge was the relocation of the entire company to the new site in Grenchen – while maintaining the production and delivery capability for our customers. Since the entire EKKO-MEISTER team was committed and contributed with great enthusiasm, it worked out well.

What surprised you the most in 2022?

Like many other companies, we thought that the worst was over after the pandemic. Few could have anticipated the massive changes in the environment and the current geopolitical situation. Many companies are still facing supply chain issues, which also affects us to some extent. One can only plan situationally and look for alternatives, if necessary. The global economy is expected to slow down, too, which will have an impact as well.

What did you enjoy most this year?

It was a Herculean task to build this new factory and relocate our entire company. The authorities, the EKKO-MEISTER team, our suppliers and our customers all did a great job. The commitment of the people was the absolute highlight for me this year.

Have the new premises already had an impact?

It’s pretty impressive how modern and state-of-the-art everything is. And the extra space has allowed us to optimize the layout and make all the processes efficient. That’s also an important factor for customers.

And in keeping with the times, everything in the new building is designed for sustainability. That’s also noticeable. Even if the snow-covered solar panels probably aren’t producing a lot of energy right now.

And what did your customers say?

The main motivation for the new building was our customers. Their orders make our business possible, and we do everything we can to offer them the best solutions and the most comprehensive service.

So, it’s rewarding that our customers are happy for us and see this move in a very positive light. Of course, they still expected on-time deliveries, high quality and favorable prices during the transition period.

And what does the future have in store?

EKKO-MEISTER AG is constantly refining its strategy and will emphatically present and expand its traditional and new activities on the market. Our wide range of technologies offers our customers new opportunities, and we are optimistic about the future.

Do you have plans for 2023 we can look forward to?

By investing in high-tech equipment, we have massively enhanced our technical capabilities so that our customers benefit from a comprehensive portfolio. We want to fully leverage this potential first. We are also shifting from mainly custom-made individual components to the development and manufacture of more complex assemblies.

As such, we have several exciting projects that are about to enter the market. These products use our entire technological base: from stamping, plastic injection molding, production automation and quality control to automated packaging.

That’s why we are currently looking for several new colleagues to join the EKKO-MEISTER team.

What are you particularly proud of?

As I’m sure everyone can guess by now, I’m most proud of the EKKO-MEISTER team’s commitment, the new building, our technology and our development in general.

Would you tell us your favorite quote?

“It is not the big that eat the small, but the fast that overtake the slow.”

Short decision-making paths and a high degree of flexibility are more important than ever. With digitization, we got used to things moving quickly. This is no different for our customers who need a solution.

Thank you so much for taking the time to talk to us, Mr. Sahli. Do you have a few parting words?

Everyone in our company contributes to customer satisfaction. We must continually become more innovative, faster and better. And we intend to always tackle any major challenges with great resolve.

Once again, I would like to thank all employees, managers, the Executive Board and, above all, our shareholders, who have all done an outstanding job to offer us this great opportunity.

At this point, I would also like to mention our customers once more, who have repeatedly placed their trust in us and have patiently supported our relocation. We thank you for your kind cooperation and hope that we will continue to meet and surpass your expectations.

And last but not least, my best wishes for your personal well-being, a blessed Christmas, and a happy New Year.

Leave A Comment