Force Majeure – Stress is optional

When you get hit by a crisis or an outright force majeure it usually creates a lot of stress for everyone involved. Fortunately, there are several levers you can use to continue supporting your customers when times get rough.

A proactive supply chain management, flexible organization, and well-defined preventive measures form the basic framework.

Another essential success factor is the relationship with your customers. Mutual trust and effective communication are crucial for agile collaboration.

If everyone is pragmatic and pulls in the same direction, we can easily manage problems together, prevent disruptions for our customers, and maybe even avoid crisis-related, additional costs.

Plastics shortage

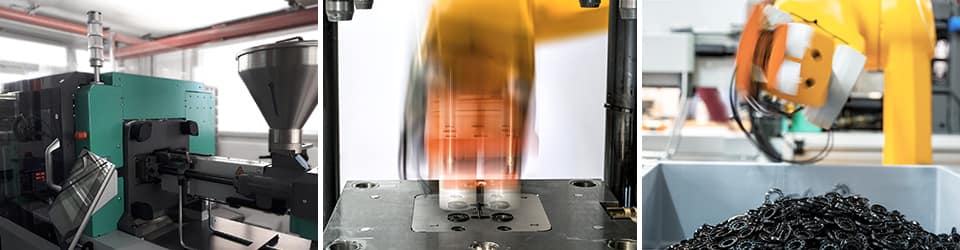

When polyamides became scarce earlier this year – to the point where many plastic manufacturers declared force majeure – our plastic injection department was also affected by this supply shortage. We mainly use engineering thermoplastics for our thrust bearing components and plastic parts and were unable to source our usual raw materials, or only to a limited extent.

Our safety stock of finished parts clearly helped us and our customers, as its buffer effect allowed us to bridge the gap for a while. And thanks to the excellent cooperation with our customers, we used this buffer period to switch our production to an alternative material.

Direct and indirect customer benefits

This not only had the immediate advantage that we were able to cope with the bottleneck and maintain deliveries to our customers. By switching to the alternative material, our customers have not been affected by any price increases so far, while the prices of the original polymer have risen sharply due to the shortage.

Be prepared

Preventive contingency plans are an absolute must if you are ISO or IATF certified and your customers naturally want to protect themselves from all scenarios. A flexible organization also makes it easier to successfully manage problem situations.

The better prepared you are for potential risks, the higher your chances of getting your customers through the crisis “unscathed”. And the better your relationship with your customers, the more open they’ll be to the necessary measures.

Especially when, as with the current plastics shortage, it will take a while before the global supply is fully restored.

Leave A Comment