Why lubricants are so important for bearings

Lubricants play a vital role in the performance and service life of ball bearings.

They minimize friction, reduce wear, and prevent corrosion and contamination.

Proper lubrication greatly increases the bearing’s service life.

But did you know that an estimated 40-50% of premature bearing failures are the result of improper lubrication?

This mostly happens when the wrong dosage, old grease or unsuitable lubricants are used.

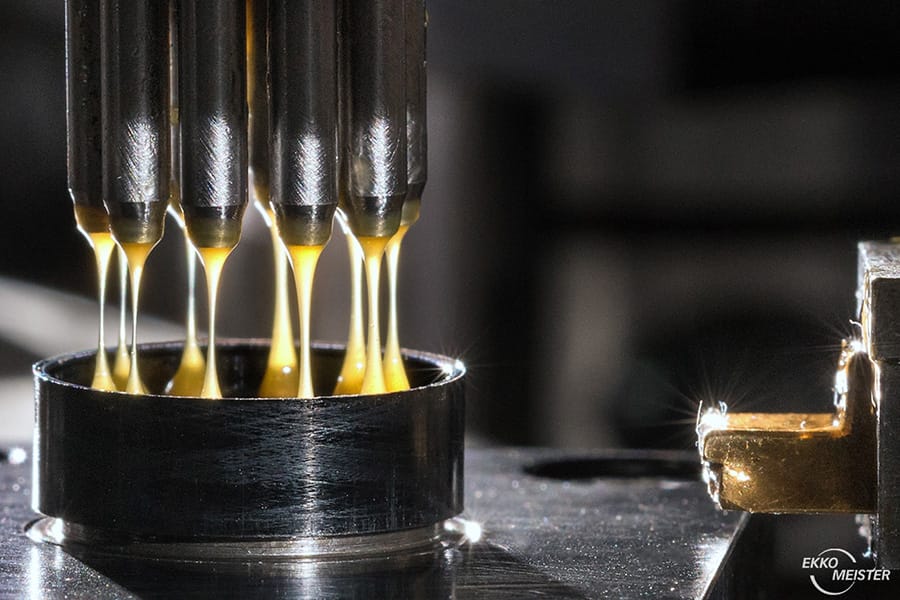

The right dosage is crucial

More isn’t always better and over-greasing is a common and costly problem.

It can lead to overheating, as well as seal damage and failure.

Insufficient lubrication also shortens the service life of your bearing.

Too little grease can cause higher temperatures and increased metal-to-metal contact which may lead to extreme wear.

As you can see, proper lubrication requires precision and skill.

And to assist you with this, Ekko-Meister AG produces both greased and ungreased ball bearings.

We are happy to support and advise you to make sure you get the best lubricant and ideal dosage for your application.

Leave A Comment