Precision metal stamping since 1945

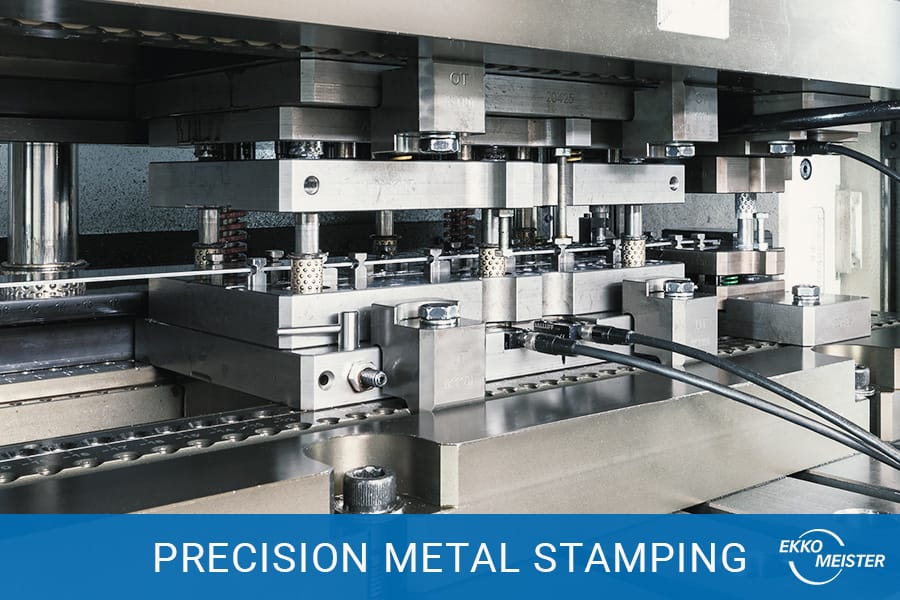

Precision metal stamping is a versatile, efficient, and cost-effective manufacturing process.

Its high automation helps reduce cost, improve quality, and produce parts with consistent accuracy.

Speed: The automation significantly cuts down production time

Accuracy: The tooling produces precise, complex shapes within tight tolerances with consistent quality

Cost: High volume automation requires little manual labor

Once we’ve designed the tooling for your custom stamped parts, we can produce thousands of high-quality metal parts per minute. These parts and components can be used across multiple industries. A few examples are the automotive sector, premium consumer goods, as well as medical engineering and the electronics industry.

Custom metal parts

Our metal stamping service offers a wide variety of high precision, custom parts. The stamped components and complex parts are made to your exact specifications so you get precisely what you need.

Using pressures of up to 51 tonnes, we manufacture precise metal parts between 0.05 and 4 mm material thickness. Depending on your stamping needs and the chosen material, we either use progressive stamping, forming, or compound dies.

Conductivity, corrosion protection, or superior hardness can be important factors for your application. This will guide the choice of material.

Typical materials include

- Steel sheet metal

- Hardened and tempered steel

- Magnetic iron

- Stainless steel

- Non-ferrous metals such as brass, bronze, copper, aluminum

- Noble metals such as beryllium copper, titanium, MU metal

Post-processing heat treating and other secondary operations can be done to your finished product to improve its properties.

And for the finishing touch, surface treatments can be added to your parts. These can improve your final product’s look or protect it against scratches or corrosion.

Examples of finishing surface treatments

- Copper Plating

- Tinning

- Nickel plating

- Silver plating

- Gilding

- Chrome plating

- Burnishing

Ekko-Meister stamping parts are used in a large variety of products and industries.

Our precision metal stamping capabilities

For optimal performance and production efficiency, we carry out in-depth feasibility studies. Depending on your stamping project, combining production processes like microstamping, metal forming, and deep-drawing enables fast and precise production.

We also determine which material you need and what the tolerances for your stamped metal parts are.

Naturally, our toolmakers make and service all tools. For you, this means quick response times, more flexibility, and competitive prices.

A flexible stamping process

Our manufacturing capabilities have a high degree of flexibility. We can adjust our stamping press, stamp guides, and stamping blocks to work at fast speeds. This makes high-volume series production very cost-effective. Depending on your custom parts’ geometry and tool design, our stamping machines can operate at up to 1,000 strokes per minute.

High volume production quantities of 100 million parts per year are not unusual. Medium quantities from 20 to 30 million parts are the norm. We also have a very cost-effective option for very small production runs and prototyping. Depending on the material and geometry specifications, we can produce quantities of just a few hundred precision metal parts. All with competitive pricing.

Strict quality standards

We believe in the continuous improvement of our stamping techniques and forming operations. And our quality control system and zero-defect principle ensure that you get the exact product you need.

Our manufacturing processes follow strict requirements and quality assurance protocols. This means we comply with demanding industry standards such as IATF.

Let’s talk about your stamping project

Precision metal stamping can save you time and money without compromising on quality or complexity.

Whether you need complex parts or simpler metal components, with millions of units, or just a few hundred…

Ekko-Meister AG is an experienced precision stamping company with the right in-house capabilities to offer you consistent, high-quality parts at competitive prices.

And we also have a plastic injection molding department if you need your stamped products for hybrid parts!

Get in touch today to discover how exactly our metal stamping services can help you!

Leave A Comment