What is this stamping part for?

Does this metal stamping part remind you a bit of a kangaroo? Can you guess what it is for?

There are 3 variants of this part – which are typically used in overvoltage protection magazines.

Overvoltages are high peaks in voltage that can damage your electronic equipment and electrical installations.

Some typical causes are lightning and faulty power equipment, but also electrical switching operations.

Switching overvoltage can happen when great charges (like generators or transformers) are switched on and off.

The more appliances homes and buildings get, the more electronic devices need protection to prevent damage.

EKKO-MEISTER uses precision metal stamping to produce very precise parts that are tailor-made to customer specifications.

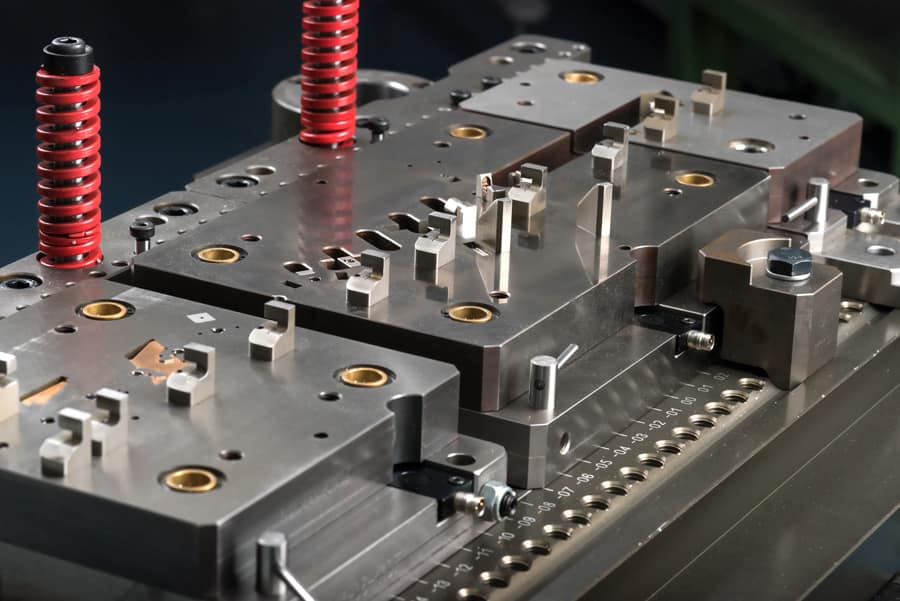

A challenging geometry

The geometric shape of these particular parts is tricky. That’s because the base area is smaller in relation to its material thickness.

Ideally, when you’re stamping, the ratio should be at least 1:1. But for these parts, the ratio is lower.

The tolerances are very narrow, too, and we naturally strive for consistently high quality. So to meet all specifications, we use integrated sliders within the stamping tool to adjust certain areas.

Get the right material

Choosing the right material for your application is also crucial. Especially when we talk about something important like electrical contacts.

These parts are stamped from bronze which then get coated with solderable tin. Tin has great conductivity, strengthens the bronze alloys and prevents oxidation.

EKKO-MEISTER AG has been producing these parts since 2004. Annual volumes range from 500’000 to 3 million parts.

And many of these are manufactured for the Asian market thanks to a great quality/price ratio.

For more information on our stamping parts, you also have this blog post on spark gaskets. Or you can get in touch with us directly. We’d love to hear from you.

Leave A Comment