May we introduce Thomas Meister to you?

Thomas Meister is an engineer in our engineering department. He enthusiastically takes care of everything that has to do with technology. Above all, he is our specialist for in-house automation projects. In his spare time, he is quite sporty and likes biking, hiking, skiing, and windsurfing.

Thomas, would you briefly introduce yourself?

When I was about 14 years old, I started working at Hans Meister AG with vacation jobs to earn some pocket money.

After an apprenticeship as a CNC polymechanic and a vocational diploma, I completed my vocational part-time studies in micro & medical technology at the Bern University of Applied Sciences. Through the study program, I deepened my knowledge in programming C++ which was the first step towards automation.

What do you do at Ekko-Meister?

My tasks are basically everything that concerns technology. So for example, 3D tool design for toolmaking, CNC manufacturing, troubleshooting tools, software – and of course automation, which is an exciting topic. For this, I also work with a 3D printer, for example, to print small grippers or guides. This saves us a lot of time and is very convenient.

What do you like best about your job?

I like the versatility of my job; I work in the office and on the shop floor. Every day is different. I continually get challenged by great new projects.

And what do you enjoy the most?

We have many interesting projects; at the moment I’m fascinated by automation.

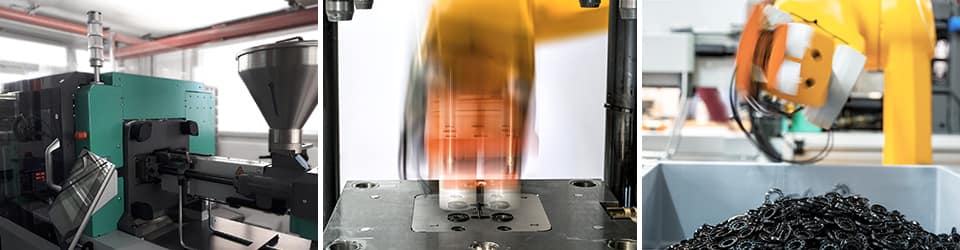

It started with our first robot that we use to pack parts. Next came plastic injection molding with a modern articulated robot. We developed the integration of this robot completely in-house.

Then came the high-speed sorting system for grooved washers, which we also developed ourselves. Above all, programming was the most fun for me. The sorting system was my first project in which I needed a PLC, so I also learned a lot of new things. That’s always exciting.

Currently, I am working on an additional automatic assembly machine for our thrust bearing production, which we are also developing 100% in-house. I enjoy almost everything about the machine, as the tasks are very varied. Construction, assembly, wiring, tubing, programming… I can also count on the help of my colleagues. We are a great team.

And how would you describe the working atmosphere?

The working atmosphere at Ekko-Meister AG is very friendly and relaxed. Everyone helps everyone.

How do you see the future of Ekko-Meister?

Since Ekko-Meister AG is very open to new technologies, the company will continue to evolve, especially in terms of quality, efficiency, and flexibility.

And with the construction of our state-of-the-art plant in Grenchen already underway, Ekko-Meister (and Thomas) can look forward to the space needed for even more intensive technological projects and progress in 2022.

Further reading about the new building (in German)

Leave A Comment