Why make it complicated when it can be simple?

Sometimes, you simply need something fast. At Ekko-Meister, we appreciate it when we can do things ourselves.

So, we invest time & money in acquiring new skills, machines, and improving our processes.

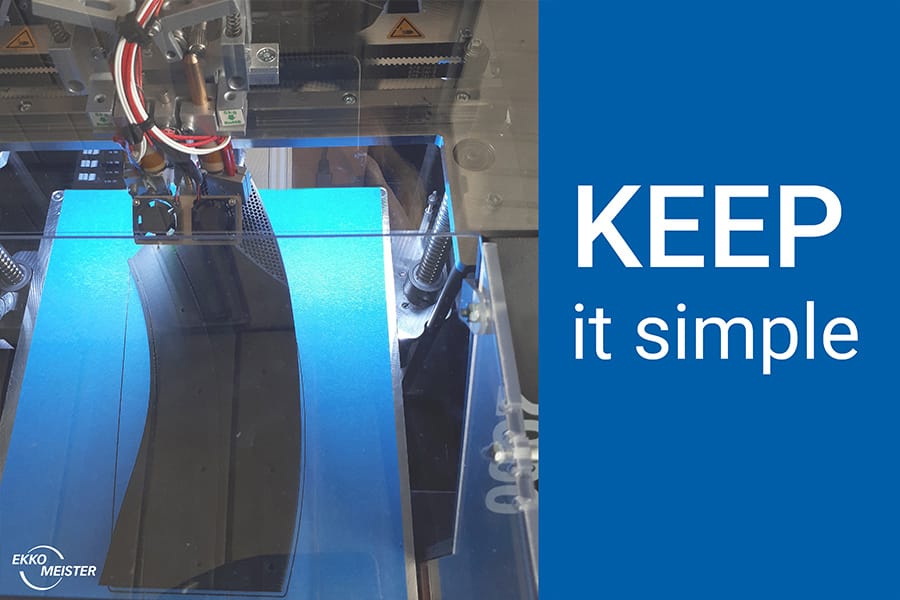

One great example is the 3D printer we got last year. It may not seem like much, but it allows us to easily make the parts we need at a low cost.

These parts, such as small grippers or guides for our automation systems, are for internal use only.

More independence and flexibility

Since we also design the CAD models for the printer, we have total freedom and save a lot of time.

And if we’re not happy with the result, we can simply make another one.

Some small parts are ready in 15 minutes… even if a complex part can take 55h to make.

It was challenging at first to figure out the printer’s various parameters. And it took many tests until we were satisfied.

But now, the parts have an accuracy of about ± 0.2mm.

So, 3D printing can be a cost-effective alternative when you don’t need a high-quality solution.

Sometimes simple means can lead to great results.

And for all parts that need to be more accurate or visually appealing, we have our high-precision metal workshop.

Problems can be complicated, solutions cannot!

Leave A Comment