Our Engineering Service with a passion for technology

We love engineering, technology, and challenging projects.

Like so many technical terms, the word technology comes from ancient Greek. It is often defined as the “science of craft”.

The root techne stands for “art, skill, cunning of hand”; and logia is the sum of techniques, skills, methods, and processes used in the production of goods or services.

Technology has a high priority at Ekko-Meister, and our employees have great engineering skills and craftsmanship. Our in-house engineering service plays a central role in successful product development and the manufacturing process.

That’s why our specialists support our customers from the very start to develop a specific, process-safe, and economical solution together with them and accompany them throughout the entire product life cycle.

No matter whether you need thrust bearings, stamped parts, or plastic and hybrid parts, and regardless of your industry.

Benefit from our engineering service and know-how

You can save time and money by involving our engineers early in your project. Benefit from our comprehensive experience in product design, process engineering, materials.

We can help you specify your thrust bearings, stampings, and plastic parts. Our engineering services will also advise you on the best material for the long-term function of your parts.

- For stamped parts, some options include DC01 steel, ferromagnetic Mu metal or Permenorm, stainless steel, beryllium copper, and titanium – with surface finishes ranging from nickel plating to gold plating

- Our thrust bearing components are typically made of brass, plastic, 100Cr6, or Inox

- For injection molding, we rely primarily on engineering and high-performance plastics

We will guide you through all phases of your project to develop the optimal, competitive solution for you.

From our engineering service to tooling and series production, you are in good hands.

And we always have perfect control over the entire product development process.

We can also provide you with active support for life cycle tests and validations.

Inhouse capacity and engineering talents

We not only develop products via CAD, but we have a direct influence on the optimization of our already lean manufacturing processes thanks to our engineering service.

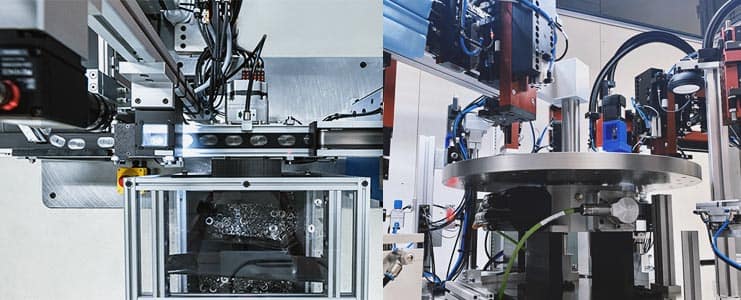

Our specialists also develop and build in-house machines that make our lives easier – and give our customers even better results.

Here are a few examples of our in-house developments:

- A robot for a variable packing and assembly machine

- The robotic integration of a modern articulated robot for our injection molding department

- A high-speed sorting system for the quality assurance of grooved discs

- To increase our capacity, we are currently developing another smart automatic assembly machine for our thrust bearing production. This is also developed 100% in-house – starting with the 3D design through to assembly and programming

With us, you get everything from one source

From basic stamped parts to complex assemblies, from simple plastic housings to geared parts with internal or external threads, as well as thrust bearing solutions with special capacities…

Our experience and enthusiasm for technology help us to carry out your projects completely in-house.

Our customers’ wishes are a driving force for the continuous development of our capabilities and capacities.

And, of course, our own drive to always deliver impeccable quality and even more comprehensive services.

We accompany your product throughout its entire life cycle. Every project enables us to learn and thus expand our know-how, which benefits all our customers.

We love technology and engineering and are already looking forward to exciting future projects.

If you need support with your project, we look forward to hearing from you.

Contact us to see what we can do for you!

Leave A Comment